TPO Overlay vs. Restoring Your Current Roof: What Texas Building Owners Need to Know

- Jesse Yutzy

- Dec 2, 2025

- 6 min read

Updated: Dec 18, 2025

TPO is an excellent roofing system. For new construction, it is one of the most economical, energy-efficient, and future-friendly roofing options available. New buildings usually have proper insulation levels, clean substrates, and structural support designed specifically for TPO.

But when it comes to re-roofing older buildings, the conversation becomes much more complex — especially when owners are comparing a TPO overlay vs. a roof restoration.

Most overlays in Texas are NOT TPO-over-TPO.They’re TPO installed over Mod-Bit, Built-Up, EPDM, or older layered systems.

This article will walk you through what building owners need to know before committing to an overlay — and why restoration often makes more sense.

Why Some Owners Consider TPO Overlays

Most building owners are pitched overlays because:

They appear cheaper than tear-off

They avoid dumpsters, debris, and downtime

They create a “brand new” look

Sales reps promise “20-year warranties”

The process sounds quick and clean

But an overlay is more than just laying a membrane over what’s already there. The existing roof becomes part of the new roof system — and if the old system has problems, you’re locking those problems in permanently.

The Real Risks of TPO Overlays on Mod-Bit, BUR, or EPDM Roofs

1. Condensation Problems Between Layers

Most older buildings do not have enough insulation to prevent heat transfer.When warm, humid Texas air hits a cooler layer under a new TPO membrane, condensation begins forming between layers — and it has nowhere to escape.

This moisture can damage the deck, insulation, fasteners, and anything below it.

(Overlays can work if insulation levels are high enough — but that is rarely the case on aging roofs.)

If any moisture already exists inside the roof assembly and you install TPO over it, that moisture becomes permanently trapped.

This causes:

Blisters

Insulation deformation

Rotten decking

Plate and fastener corrosion

As fasteners sit in damp or compromised insulation, they begin to rust out — and as that happens, the membrane loses its attachment. Within a few years you can end up with a loose-laid, poorly secured system, even if it looked perfect on day one.

3. Structural Load Concerns

A second full membrane system adds weight.Many older commercial buildings were not engineered for multilayered roofing systems.

An engineer should always confirm load capacity before approving a TPO overlay.

4. Adhesion & Material Compatibility Issues

Mod-Bit, asphalt, EPDM, and Built-Up roofs respond to heat differently.TPO adhesives often do not bond properly to these surfaces without correct preparation.

This can lead to:

Wrinkles

Tenting

Premature membrane failure

Pulling at penetrations and edges

5. Asbestos Considerations

Many older Mod-Bit and BUR roofs contain asbestos in the lower layers.

A TPO overlay does NOT encapsulate asbestos safely or meet best-practice standards for long-term stability.

A restoration system, such as SPF + coatings, encapsulates the substrate without disturbing it, reducing future abatement concerns and creating a seamless, fully adhered surface.

(See Case Study #1 below.)

6. Warranty Misrepresentation (The Fine Print Trap)

It’s extremely easy for a roofer to file a TPO membrane warranty with the manufacturer.Manufacturers often issue the warranty number with no upfront questions or inspections.

But in the fine print, that warranty is only valid if:

The contractor is certified

The underlying roof assembly matches an approved system

Proper fasteners, adhesives, boots, and terminations were used

Welds are tested and inspected

A manufacturer’s representative performs required inspections

Most cheap overlay crews do none of that.

The customer thinks they have a 20-year warranty when, in reality, the manufacturer has every reason to deny a claim.

7. Leak Tracking Is Much Harder on Overlays

Building owners often ask:

“Why is a restoration any different from an overlay when it comes to leak diagnosis?”

Here’s the difference:

TPO Overlay

Water or condensation can travel between the layers of the existing roof and the new membrane.This makes leaks extremely difficult to trace.

Restoration System

A restoration creates one monolithic, seamless surface.There are no loose layers for water to run between.

If there’s a breach, it’s straightforward to locate and repair.

When a TPO Overlay Can Work

An overlay is only appropriate when ALL of the following are true:

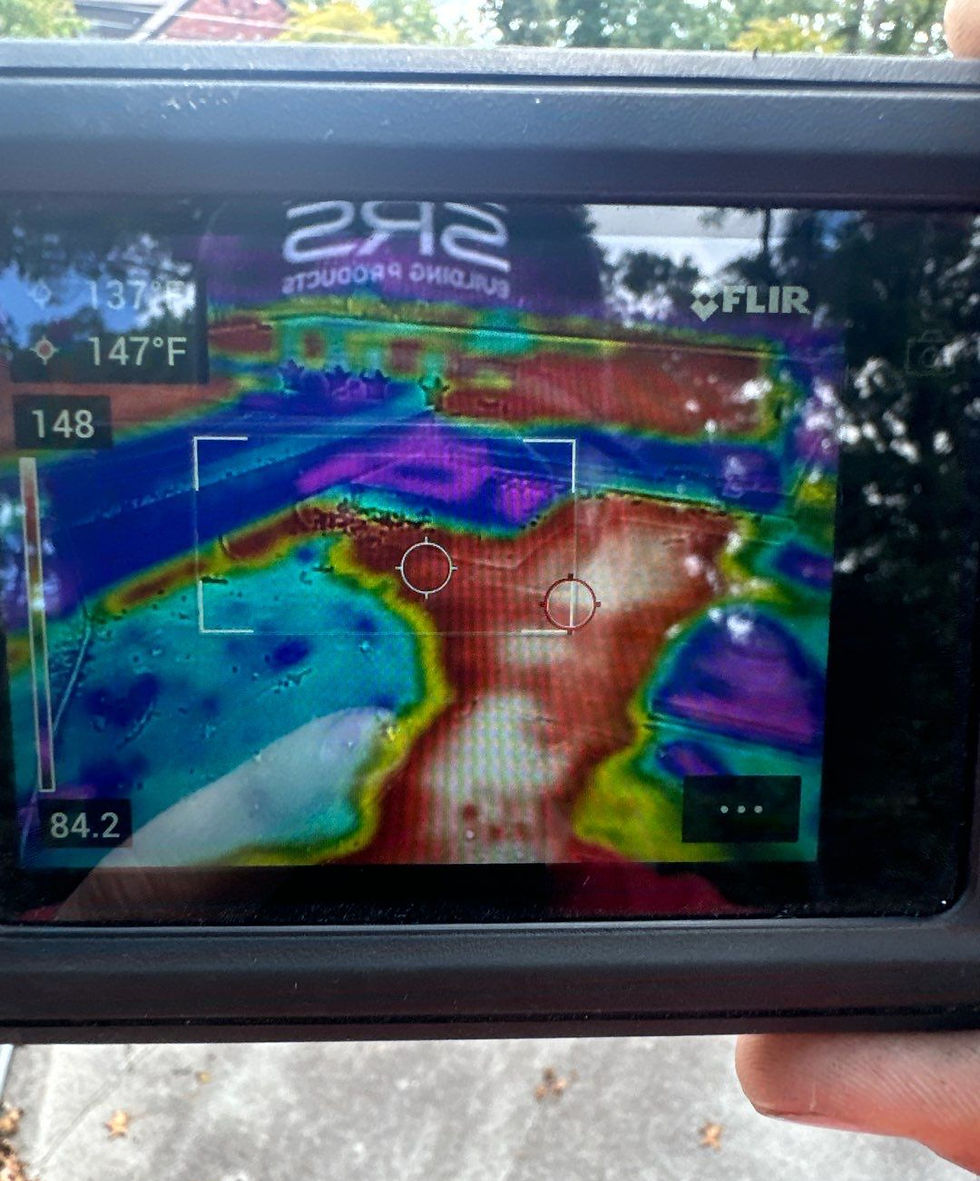

Moisture scan shows zero trapped moisture

Insulation levels are high enough to minimize heat transfer

Deck is structurally sound

Existing roof is fully adhered and smooth

Current roof system is compatible with TPO (Thermo Plastics)

Structure can support added weight

Full manufacturer specs are followed

Contractor is certified

Engineer signs off on the system

This eliminates the majority of low-bid overlay proposals.

When Restoration Is the Better Choice

Restoration systems (SPF + coatings or reinforced acrylic/polyurea systems) often make more sense on aging Mod-Bit, BUR, or single-ply roofs because:

They add minimal weight

They produce a seamless, monolithic surface

They encapsulate older layers (even asbestos-containing ones)

They greatly improve reflectivity and energy efficiency

They can be renewed at the end of the warranty

They avoid the risks of condensation and trapped moisture between layers

But restoration is NOT a cure-all.

If the substrate becomes too saturated, restoration won’t work. At that point, the conversation shifts from overlay vs restoration to tear-off — and then it becomes a completely different conversation about which system to install next.

Case Studies (Canton, TX)

Case Study #1 — Smooth Mod-Bit with Potential Asbestos

The owner was considering a TPO overlay. After evaluating the roof, we found:

Potential asbestos in original layers

TPO overlay would not safely encapsulate it

Tear-off would require costly abatement

A restoration system could be installed without disturbing the substrate

Solution: SPF + Coating Restoration

Seamless and fully adhered

Encapsulated potential asbestos

Reflective

Added insulation

Eligible for non-prorated, extendable warranties

Can be renewed with additional coating later instead of tearing off

Completed SPF and coating restoration providing a seamless, reflective commercial roof in Kilgore, Texas.

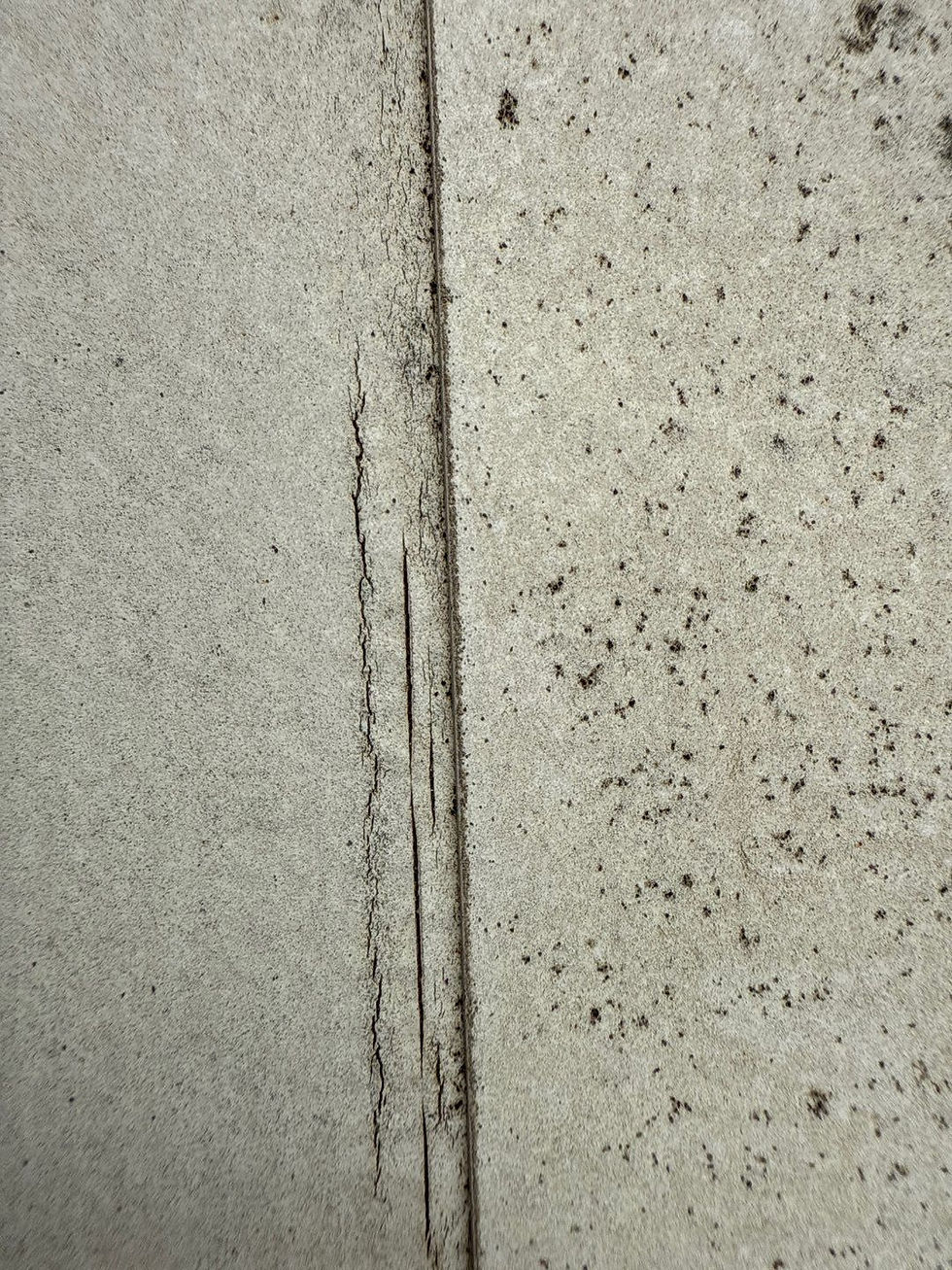

Case Study #2 — Aged TPO with Failing Seams

This owner considered tearing off the TPO and installing new TPO.

After evaluating, we recommended TPO restoration instead of replacement.

Benefits:

Lower cost

Same warranty length

Seamless (no more welded seams to fail)

Higher reflectivity

No tear-off required

(This topic — TPO Restoration vs Replacement — will be its own blog article.)

What Fly-By-Night Installers Commonly Do Wrong

Most cheap overlay crews cut corners on:

T-patches

Parapet wall adhesion

Proper fastening patterns

Using correct pipe boots and pitch pockets

Proper terminations

Adding slope

Running welders too hot or too cold

Test welds (we perform them every 10° of temperature change)

Material compatibility

Moisture testing

Engineering load approval

Manufacturer certifications

Using DensDeck on hail-prone buildings (critical for TPO longevity)

These shortcuts lead to premature failure, even on a brand-new roof.

What Makes All Star Roofing Different

We do things the right way — even when it costs us more.

Manufacturer-spec installations

Engineer-reviewed overlays only

Moisture scans before ANY overlay or restoration

Pre-manufactured boots and pitch pockets

Test welds performed every 10° temperature change

Optional (but strongly recommended) DensDeck for hail resistance

Proper parapet termination

Certified installers only

Seamless restoration options for long-term value

Non-prorated, extendable warranties

We educate owners honestly — even when the right decision isn’t the most profitable for us

Because at the end of the day, we want your building to last — not just get a new roof “look.”

Need Help Deciding Between a TPO Overlay or a Restoration?

Every roof is different.

We’ll evaluate:

Moisture levels

Insulation

Structural load

Deck condition

Warranty goals

Hail exposure

Energy efficiency needs

…and give you the truth, not a sales pitch.

📞 Call All Star Roofing LLC: 903-368-8684🔍 Or request an inspection at ASR.LLC

FAQ

Q: Is a TPO overlay a good idea on an older Mod-Bit roof?

A: Only if moisture, insulation, structure, and compatibility all meet strict requirements. In many cases, a restoration is safer and more cost-effective.

Q: Can restoration be done on asbestos-containing roofs?

A: Yes. SPF and coating systems can encapsulate potential asbestos without disturbing it.

Q: How long does a restored roof last?

A: Many restoration systems offer non-prorated warranties of 10–20 years and can be renewed later.

Q: What happens if I wait too long to fix a leaking roof?

A: Once insulation becomes saturated, restoration is no longer viable, and a full tear-off is required.

Comments